The transition from our current fossil fuel-focused energy system to a one based mainly on renewable energy generation will introduce new challenges, the two main ones being the intermittent nature of renewables and the fact that not all sectors of society can be easily electrified.

The above is supported by a new Doctor of Science research paper by Lauri Järvinen Lappeenranta-Lahti University of Technology LUT, Finland.

One technology provides a clear path to overcome these challenges, and that is water electrolyzers, which in combination with renewable energy generation can be used to produce green hydrogen.

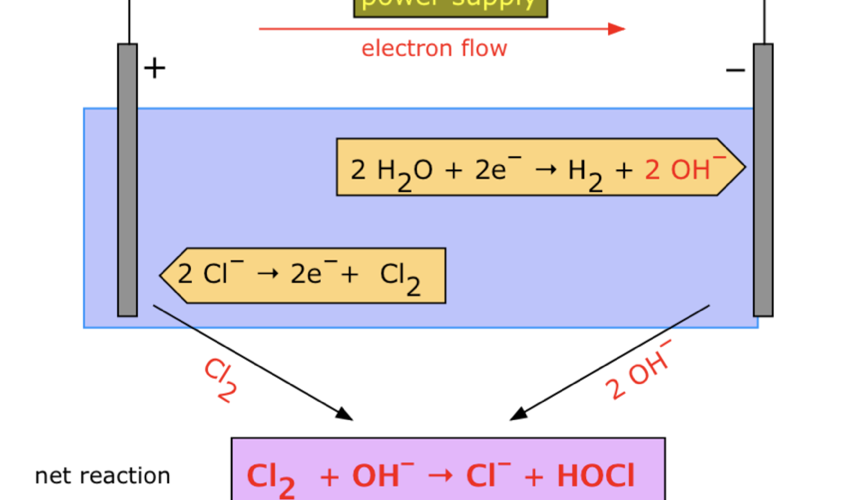

Water electrolyzers operate by splitting water molecules into hydrogen and oxygen by using an electrical DC current. Green hydrogen can be used to bridge the gap between the renewable energy sector and sectors such as the steel, chemical, and heavy transportation industries.

Additionally, hydrogen or other chemical compounds based on it can be employed to store excess electricity in a chemical form, which can then be utilized as an intermittent energy storage. Currently, only 0.1% of the hydrogen is produced using water electrolysis; the majority of the production is carried out applying steam reforming, which produces large amounts of CO2 to the atmosphere. Thus, a large increase in electrolyzer deployments is needed to meet the growing demand for green hydrogen.

As water electrolyzers are scaled up, the power supply to the electrolyzer becomes more complicated. The AC current from the electricity grid has to be rectified to DC, which is currently done mainly by using thyristor bridge rectifiers. These rectifiers cause high-frequency ripple (≥ 300 Hz) in the electrolyzer supply current. In addition to the ripple coming from the rectifiers, renewable energy sources can cause lower-frequency ripples (< 1 Hz) in the supply current, leading to dynamic operation.

Thus, studying the dynamic operation of the electrolyzer is of major interest.

This doctoral dissertation sheds light on the effects of rectifier-induced dynamic operation on the controllability and performance of alkaline water electrolyzers. The measurements conducted in the study show a clear increase in power usage when the electrolyzer supply current has ripple.

The losses increase as a function of ripple amplitude; up to a 5.5% higher power usage is observed at the 100% ripple amplitude. Ripple frequency is found to counteract the losses, and it is shown that increasing the frequency from 10 to 1000 Hz can reduce the losses by up to 33%.

Based on the results, modern rectifier topologies should be considered that would provide lower ripple amplitudes and a higher frequency, which in combination should significantly reduce the ripple-induced losses. The dissertation also investigates the linearization of electrolyzer behavior as the frequency of the dynamic operation is increased. Frequency limits at which an alkaline electrolyzer cell can be modeled as a linear impedance component are defined for two different electrode sets.